Starting at $23,800

Edge Series Details

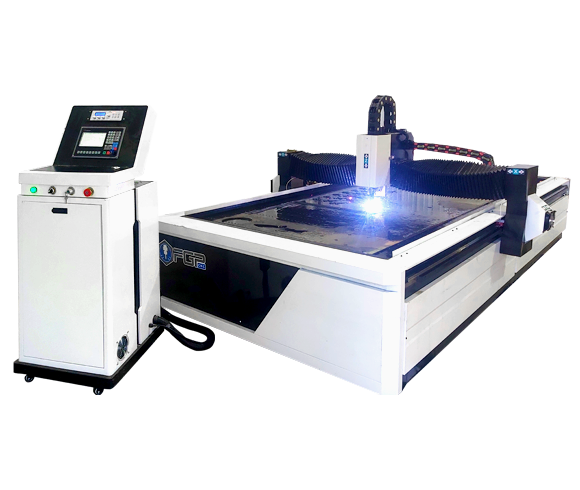

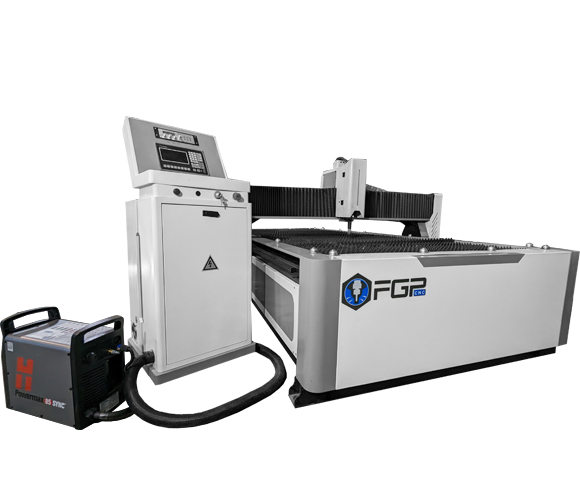

We always have a stock of CNC Plasma Tables available for you. Heavy-weight, extremely powerful, and versatile, the possibilities are endless with our plasma cutters. These machines do not lose their market value, and even after many years of use, we can still trade or sell the unit for you.

Some standard features include:

- Steel frame construction

- 25mm linear rails

- Helical low backlash rack and pinion

- Hybrid motors with an encoder feedback loop for higher accuracy

- 60A to 125A plasma powers

- Stand-alone controller with touchscreen and easy job loading

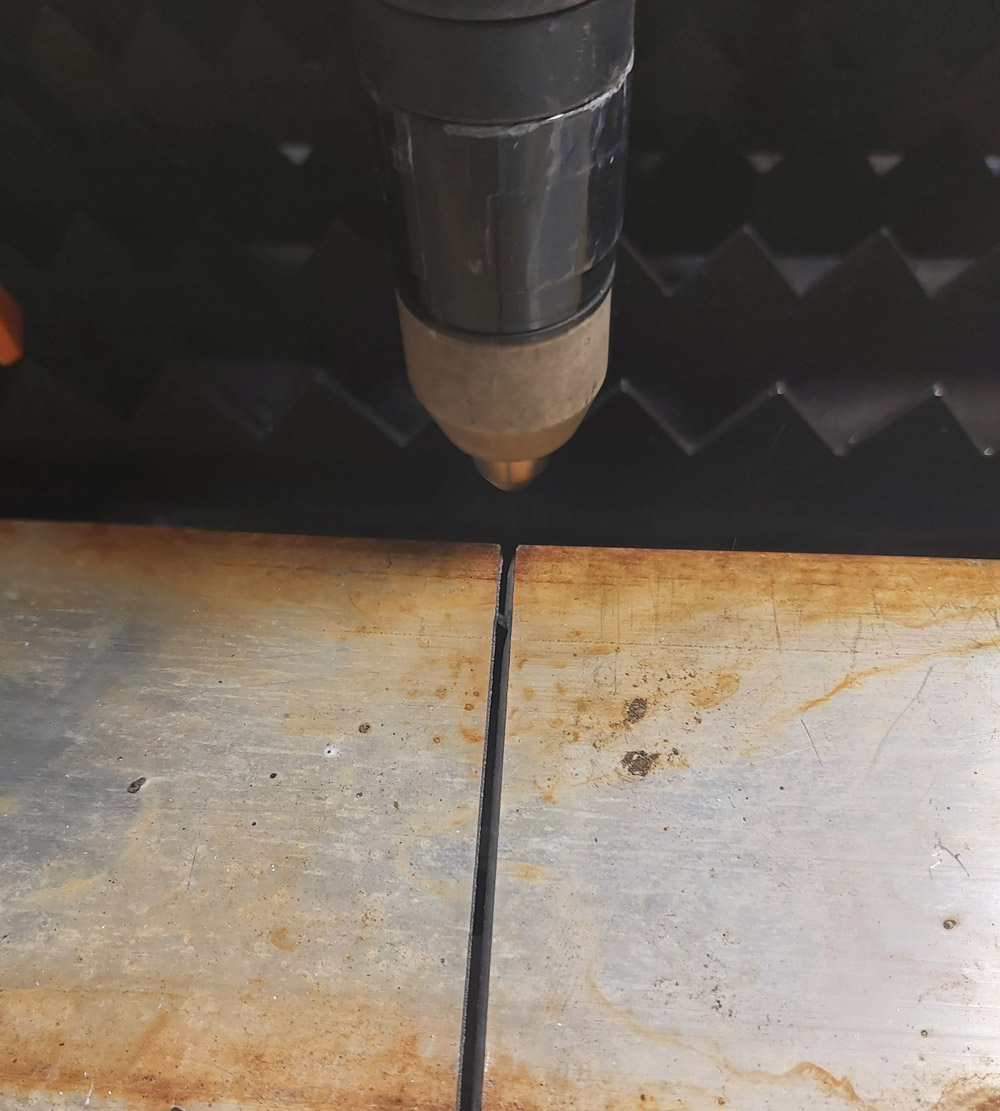

- Torch Height Controller with raw volt feedback

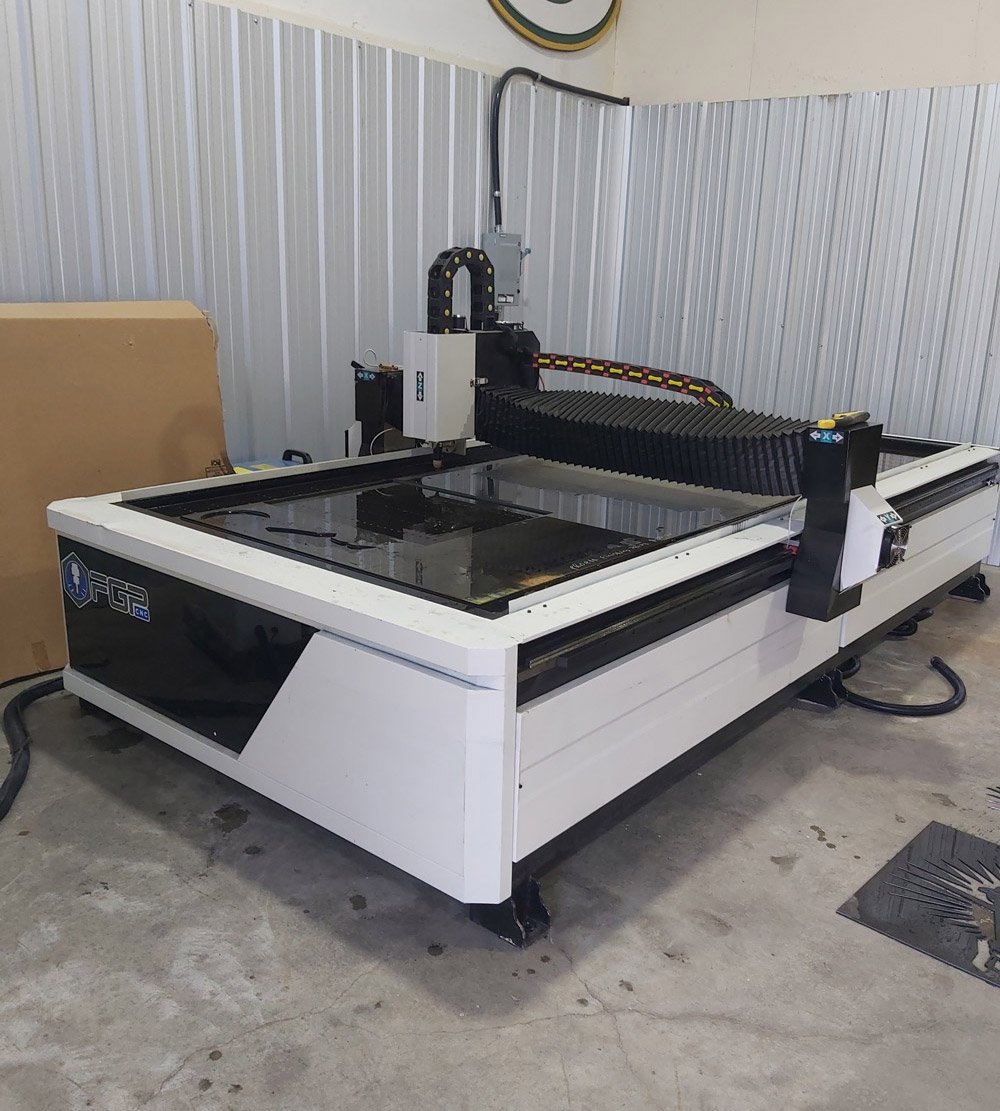

- Waterbed or HVAC table options

FGP provides onsite training, support, and remote login assistance

SOFTWARE TRAINING: FGP is the ONLY company that includes FREE installation and training for all its customers. This training includes machine operation and basic CAD/CAM programming. At the end of the training, any operator can design a job, create machine code and run their CNC!

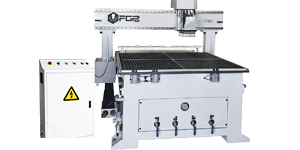

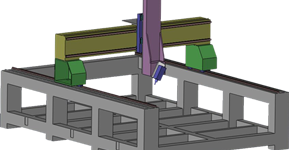

Edge Series Photos

Edge Machine Specs

| SPECS | |

|---|---|

| Table Size | 4’x4’ (1300 x 1300mm)

4’x8’ (1300 x 2500mm) 5’x10’ (1500 x 3000mm) |

| Frame | Heavy duty steel frame, heat treated and stress relieved |

| Plasma Power | Options to choose are available

Hypertherm , Miller, Chinese OEM 60A to 125A |

| Torch Height Controller | Standard with all models |

| Linear Motion | Taiwan HIWIN 25 mm rails for X,Y |

| Transmission | Taiwan Miko Helical rack and pinion for X,Y

Taiwan TBI ball screw for Z Optional: All-axis ballscrew transmission system. |

| Motors and Drives | Hybrid / Servo motors with closed-loop feedback |

| Table | Steel grill table top with waterbed or HVAC |

| Controller | Stand-along touchscreen Starfire control system with graphical user interface |

| Lubrication | Maintenance-free self-lubricating bearings |

| Travel | 900 IPM rapid travel |

| Install & training | FGP offers free installation and training on all machines! Training in software, CNC, design, CAM, and maintenance |

Standard Features

- Industrial plasma cutting table with waterbed / HVAC

- 25mm linear rails and low backlash helical racks

- 60A to 125A plasma cutter for steel and stainless

- Torch height controller to follow material with raw voltage feedback

- Onscreen assistance and job simulation

- Touchscreen control interface with easy load and shape library

- Manual override of spindle speed and feed speed during runs

Software

- Machine runs on standard Gcode

- Machine is compatible with most industry CAM/CAD software

- FGP can provide CAM/CAD design software for 2 D/ 3 D production. We recommend VCarve Pro; AlphaCam; Enroute; Artcam. We can provide machine compatible software for cabinet and custom furniture design.

Edge Manuals

FGP CNC Products

We design and manufacture computerized 3 Axis and 4 Axis router tables, 3 Axis Laser cutting machines, and plasma tables.

Request a Quote

Please fill out the form below for buying, selling, trading or technical support inquiries. We reply back within 24 hours to assist you with your quote.