CNC repair gantry square

From time to time a CNC gantry moves out of square and needs to be readjusted back into alignment. Older machines tend to have one motor driving the gantry up and down the long axis, but with the reduction in pricing of motors, most new routers have two driving motors. This causes machines to go out of square more frequently if motors are

not synced; still, it is also easier to re-adjust the gantry square.

Determine if your gantry is in square or out of square

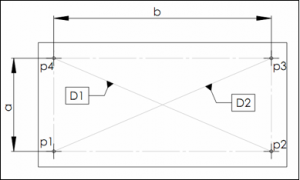

Place a sheet of MDF on your CNC tabletop and create 4 points to make a rectangle, make the rectangle as big as possible. You could also cut a shallow rectangle on your MDF 1/16″ deep with sharp corners. similar to the image below

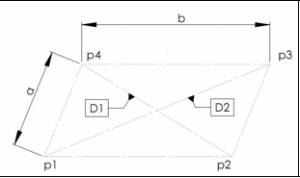

Now that you have your rectangle, measure between 4 corners diagonally. If the CNC gantry is square, then both corner-to-corner diagonal lines should measure the exact same. For most users, 1/32″ difference over the length of the whole table is acceptable. But if you are trying to achieve a higher accuracy of less than 3 thou, then you might need to adjust this closer to zero difference between the two diagonal lines.

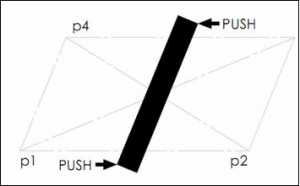

If for instance, the image below shows diagonal lines D1 is smaller than D2 which indicates instead of a rectangle we have a rhomboid and that helps us determine which side of the gantry needs to be pushed.

Methods to repair an out of the square gantry

1) Rack and pinion method

- If gantry only needs a minimal adjustment of less than 1/32″ then you could

- Power ON all the motors, so they are holding the position

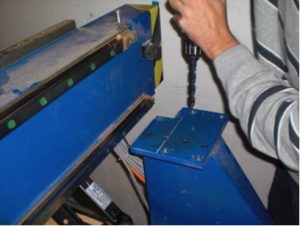

- Disengage rack and pinion on one side of the gantry by opening motor mounting bolts

- Without rack and pinion engagement, push or pull one side of the gantry and then re-tighten the motor mounting plate. Make sure there is no play between the rack and the pinion. Read more about this in our backlash repair section.

2) Re-positioning gantry uprights

- This is a harder method and you should try to avoid it if possible. We have a video that might help you opening and re-aligning the gantry

- In this method, you need to open all the bolts holding the gantry to the upright on one side. Do this while the machine is still ON and motors are holding the position

- Once you loosen the gantry beam from the uprights, then either:

- Push/pull gantry beam using clamps or crowbar. You are only moving the gantry beam and not the uprights.

- Or raise the gantry and completely lift it off the uprights. Then you can move it back to square

- NOTE: this method is only possible if you have oversized holes between the gantry beam and the uprights.

3) Automatic gantry square using sensors

This is by far the easiest way to put your gantry back into square. We add this feature to most of our CooperATC and some of the base RIG models.

In this method, there is one homing sensor on either side of the gantry. Simply “home” your CNC router and motors will push themselves into square by finding two separate homing sensors.

This is hard for end-user to implement if your machine doesn’t already have it. Contact us for assistance